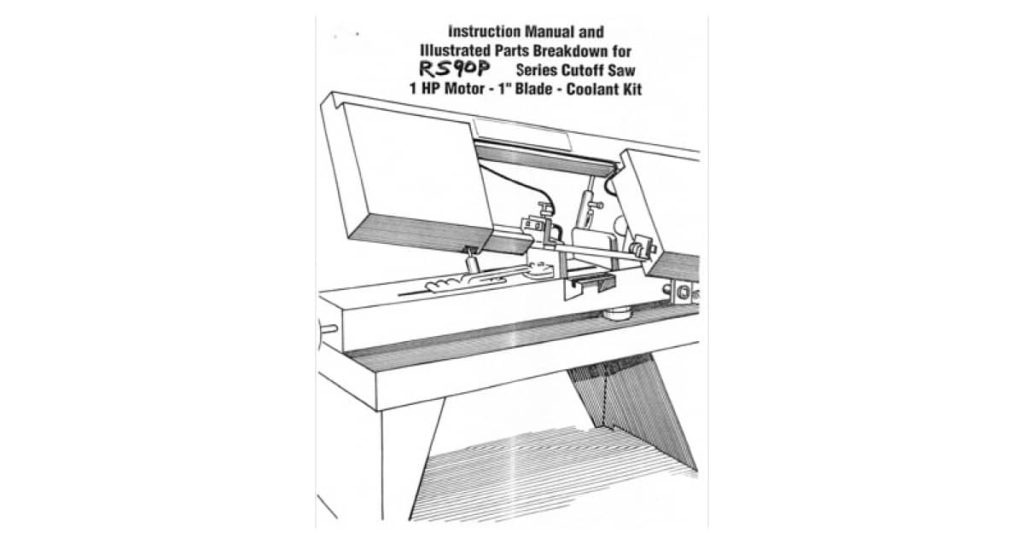

Why Understanding RS-90P Components Matters

The Ramco RS-90P is valued for steady performance, but like any metal-cutting bandsaw, it relies on well-maintained parts to run smoothly. When operators understand how each component functions, they can reduce downtime, keep cut quality consistent, and extend the machine’s lifespan. Whether the RS-90P is used in fabrication shops or light production settings, knowing its key parts supports predictable and accurate cutting.

Main Parts Found on the Ramco RS-90P

• Blade guides

• Drive belt

• Upper and lower wheels

• Motor assembly

• Tension system

• Hydraulic feed components

• Gearbox

• Vise and clamping hardware

• Blade guards

• Control switches

• Coolant pump and lines

How the Blade System Affects Performance

The blade, guide bearings, and tension assembly work together to keep cuts straight and steady. If the blade begins to drift or if guide components show wear, accuracy declines. The RS-90P relies heavily on proper tracking, so misalignment or worn guides can lead to rough surfaces or shortened blade life.

The Importance of the Gearbox and Drive Components

The gearbox converts motor output into a stable blade speed suited for metal cutting. When seals wear or gears begin to loosen, heat, leaks, or erratic speeds can occur. The drive belt also plays a key role if it weakens or slips, the blade speed becomes inconsistent, affecting cut quality.

Need Manuals for Your Bandsaw?

If you’re looking for accurate diagrams, parts lists, or setup instructions for your machine, bandsawmanuals.com is a reliable resource worth checking out. The site offers free access to a wide range of bandsaw manuals, making it easier to identify components, verify specifications, and keep your saw running smoothly. It’s a helpful tool for anyone maintaining or repairing a bandsaw, whether in a shop or on the job.

RS-90P Bandsaw Parts Reference Table

| Part Type | Function | Signs It Needs Replacement |

|---|---|---|

| Blade Guides | Maintain blade stability | Vibration, uneven cuts |

| Drive Belt | Transfers motor power | Slipping, burning smell, slow startup |

| Gearbox | Regulates blade speed | Oil leaks, heat, noise |

| Tension Assembly | Maintains proper blade stress | Tracking issues, loose blade |

| Vise/Clamp | Holds material securely | Stock shifting during cutting |

| Coolant Components | Reduce heat and friction | Low flow, clogging, pump noise |

Why Feed and Clamping Parts Matter

The vise and hydraulic feed system influence cut pressure and material stability. If the feed pushes too fast or too lightly due to worn parts, it can damage the blade or produce inaccurate cuts. Keeping these components in good condition ensures smoother, safer operation.

Common Replacement Parts for the RS-90P

• Guide bearings

• Blade tension springs

• Drive belts

• Electrical switches

• Hydraulic seals

• Coolant hoses

• Vise screws and plates

How Regular Maintenance Extends RS-90P Service Life

A routine that includes cleaning chips, checking lubrication, inspecting the drive belt, and keeping blade tracking aligned helps prevent mechanical failures. Even small issues—such as worn guide bearings—can affect cut accuracy if ignored.

Typical Signs Your RS-90P Needs Attention

• Blade drifting during cuts

• Loud or uneven motor noise

• Excess heat while running

• Poor coolant flow

• Slower cutting speed

• Noticeable vibration

Interested in Increasing Your Bandsaw’s Cutting Height?

If you’re thinking about boosting your saw’s capacity for thicker hardwood cuts, you’ll want to take a look at our guide “Upgrading Your Bandsaw with a Riser Block Kit: Is It Worth It for Hardwood Resawing?” This article explains how riser block kits change cutting height, what to expect during installation, and whether the upgrade makes sense for your shop. It’s a helpful resource if you’re comparing options or looking to improve your resawing setup.

Best Practices for Replacing RS-90P Parts

• Verify that replacement parts match the RS-90P model

• Inspect related components when diagnosing a failure

• Replace guide bearings or guide blocks as a set

• Re-tension belts after installation

• Use trusted aftermarket parts if OEM parts are unavailable

Maintaining consistent performance on the Ramco RS-90P depends on understanding its major components, recognizing early wear, and replacing parts before they affect operation. With proper care of the blade system, gearbox, feed controls, and coolant setup, the RS-90P remains a dependable tool for daily metal-cutting work.