Why Upgrade Your Guides

Dayton bandsaws are dependable machines for woodworking tasks of all kinds. Over time, however, standard guide blocks can wear down, which leads to added friction, extra heat, and blades that wear out faster. Replacing them with roller-bearing kits or phenolic cool blocks gives smoother operation, longer blade life, and more accurate cuts.

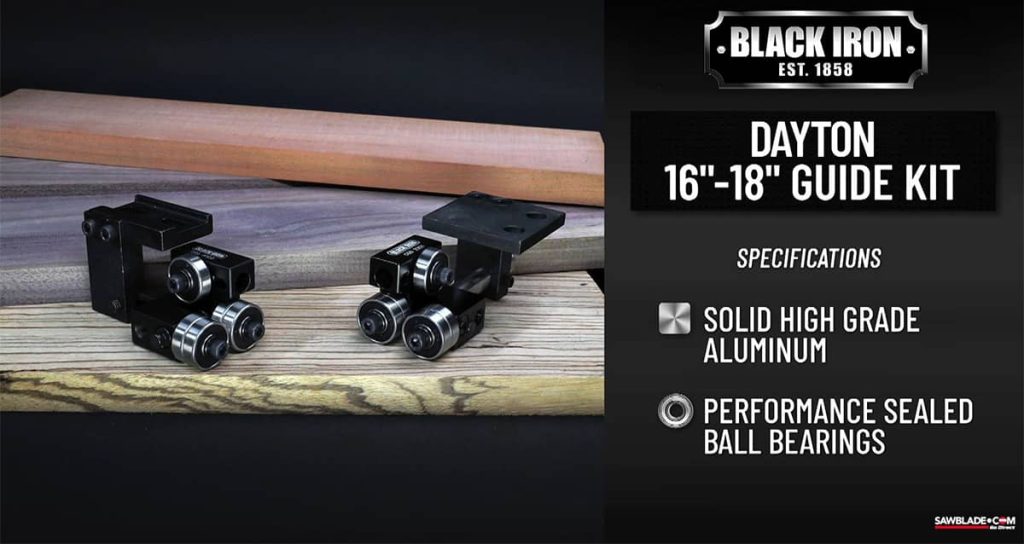

Inside the Dayton 16/18″ Conversion Kit

-

Upper and lower precision guides

-

Mounting studs and brackets

-

Hardware and screws

-

Guard adapter bracket if required

Roller-Bearing Guide Advantages

Roller-bearing upgrades improve blade tracking and reduce resistance. This results in cleaner cuts, reduced vibration, and longer service life for your blades. Their durable build makes them a strong choice for tasks such as resawing thick material while still being easy to install.

The Case for Cool Blocks

Cool blocks are made from phenolic infused with graphite and offer a gentler contact with the blade. They help keep blades cooler, reduce noise, and extend blade life. They are not as rugged as bearings but are a low-cost way to improve performance.

Quick Feature Comparison

| Feature | Roller-Bearing Kit | Cool Blocks |

|---|---|---|

| Accuracy | High | Medium |

| Heat Control | Strong | Moderate |

| Blade Life | Extended | Extended |

| Noise | Normal | Quiet |

| Price | Higher | Lower |

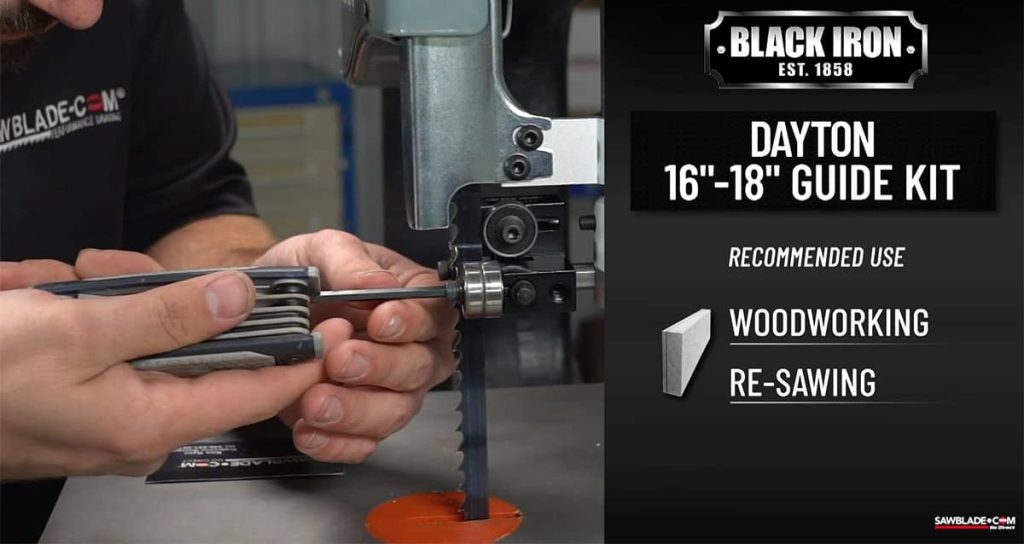

Installation Summary

The upgrade process is straightforward. Remove the original guides, clean the mounting area, and fit the new components with the provided hardware. Adjust the spacing so that the bearings or blocks are close to the blade without adding pressure. Re-tension the blade, then perform a test cut to ensure proper tracking and smooth results.

Built to Last

-

Crafted from high-grade 6061 aluminum

-

Sealed bearings to keep dust out

-

Engineered for frequent use and demanding cuts

Supported Blade Sizes

This conversion kit works with blade widths from 3/16″ up to 3/4″, making it useful for both fine curve work and heavy resawing.

What Users Notice

Many woodworkers report straighter tracking, fewer vibrations, and better consistency once the kit is installed. Blade changes are less frequent since the upgrade reduces stress and extends blade life.

Key Takeaways

-

Cleaner and more precise cutting

-

Longer-lasting blades

-

Greater reliability for resawing and everyday work

-

Improved overall performance of the bandsaw

Learn More About the Delta 28-475X

If you’re interested in bandsaws with advanced design, check out our article “Delta 28-475X: Rare Bandsaw with Professional Features.” It explains what makes this model stand out, from its build quality to the features that appeal to serious woodworkers. A great resource if you’re exploring options for precision and reliability.

Upgrading the guide blocks on a Dayton bandsaw is one of the simplest ways to improve accuracy and cut quality. Roller-bearing kits are best suited for heavy-duty work, while cool blocks provide a quieter, affordable upgrade. Either choice brings noticeable improvements in smoothness and efficiency.