Why Improving Your Guide System Makes a Big Difference

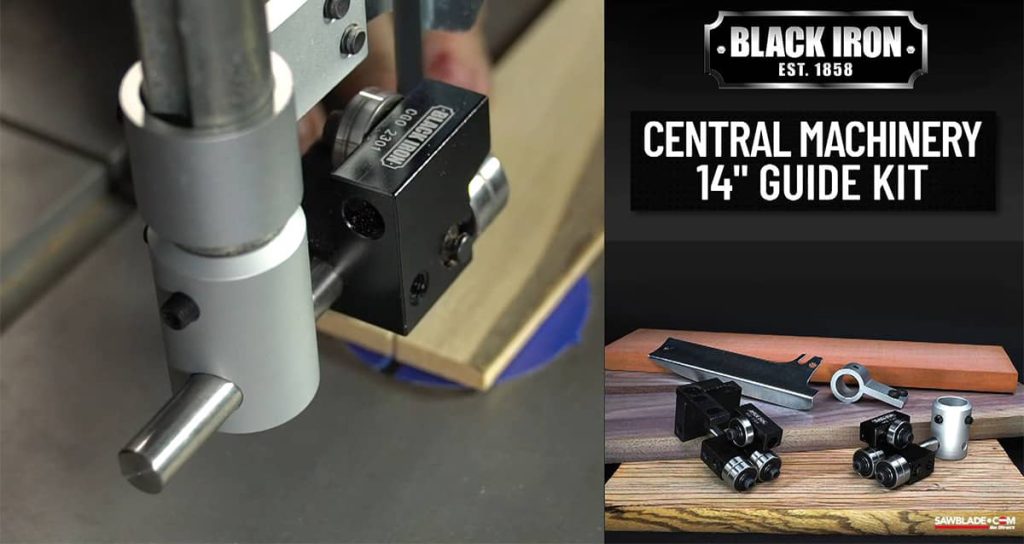

Central Machinery 14″ band saws are patterned after the classic Delta-style machines. They handle everyday tasks well, but the original guide blocks commonly plastic, phenolic, or lightweight aluminum don’t always offer the precision or durability needed for demanding work. They can run hot, shift during heavy cuts, and offer limited support for wider blades. Upgrading to a sealed roller-bearing guide system instantly boosts blade stability, reduces vibration, and delivers cleaner results. Kits from GuideKits or SawBlade.com are engineered for these saws, using rigid brackets and long-lasting bearings that match the typical post sizes found on Central Machinery models.

Steps for Selecting the Right Guide Kit

-

Measure the diameter of the upper guide post

-

Identify whether the post is round, stepped, or hex-shaped

-

Choose between standard or wide-capacity roller guides

-

Ensure the kit supports the blade widths you rely on

-

Determine if you need an adapter ring or sleeve

-

Check the manufacturer’s compatibility notes

-

Consider whether resawing will be a regular operation

-

Double-check your measurements before purchasing

Understanding Guide Posts and Blade Requirements

Central Machinery 14″ saws have been built with several post configurations. Most models use 7/8″ or 3/4″ round posts, though a few older versions feature a hex post. Getting the measurement right ensures the new guide fits securely and adjusts properly. Blade width matters, too: if you use 3/4″–1″ blades for resawing, a heavy-duty kit is ideal. For general work typically 3/16″ to 1/2″ blades—a standard kit offers the right balance of support and adjustability.

Why Roller Bearings Outperform Traditional Guide Blocks

Roller guides dramatically reduce blade friction and help maintain a steady cut path. Standard blocks can wear unevenly or create heat buildup during extended cuts. Upgraded roller assemblies offer:

-

Lower friction and cooler blade operation

-

Improved tracking and cut accuracy

-

Better support for narrow blades

-

Cleaner edges when resawing

Comparison of Guide Kit Options for Central Machinery 14″

| Feature | Standard Roller Kit | Heavy-Duty / Wide-Blade Kit |

|---|---|---|

| Blade Range | 3/16″–1/2″ | 3/4″–1″ |

| Post Compatibility | 7/8″ or 3/4″ | 7/8″ or 3/4″ |

| Bearing Size | Standard sealed bearings | Larger, high-capacity rollers |

| Best For | General woodworking | Regular resawing |

| Adjustment Capability | Moderate | Wide lateral adjustment range |

| Adapter Needed? | Sometimes | Sometimes |

Installing Your New Guides

Once you’ve confirmed compatibility, installation is usually straightforward. Remove the original blocks, clean the mounting areas, and position the new brackets so they sit flat and square. Install both the upper and lower assemblies loosely so they can be aligned after the blade is reinstalled and tensioned. Making fine adjustments with the blade under proper tension provides the most accurate setup.

Installation Checklist

-

Unplug the saw and remove the blade

-

Verify the guide-post diameter

-

Clean mounting surfaces of dust and debris

-

Install any necessary adapter components

-

Mount the lower guide bracket

-

Attach the upper guide assembly

-

Reinstall and tension the blade

-

Adjust the thrust bearing for minimal contact

-

Set side bearings with a small clearance

-

Spin wheels by hand to check for rubbing

-

Test-run the saw to confirm proper operation

When to Recheck Your Guide Settings

After upgrading, your settings typically stay stable, but a few situations call for a quick tune-up. If the blade starts drifting, makes unusual sounds, or shows uneven wear marks, the side bearings or thrust bearing may need adjustment. Changing blade widths will also require resetting the guides.

Common Guide Issues and Fixes

-

Blade drift: verify tension and side-bearing spacing

-

Burn marks or heat: reduce side-bearing pressure or inspect blade condition

-

Thrust bearing noise: back it off slightly

-

Rollers not spinning: clean or replace bearings

-

Blade creeping forward: adjust thrust bearing position

Choosing a Guide Kit for Your Cutting Style

Different woodworking tasks benefit from different guide designs. Resawing requires stronger bearings and wider brackets to stabilize broader blades. Curve cutting, on the other hand, benefits from guides that allow very close, precise support around narrow blades.

Ideal for Resawing

-

Larger thrust bearings

-

Wider roller assemblies

-

More rigid lower bracket

-

Built for 3/4″–1″ blades

Want More Accuracy? Learn How to Set Guides for Any Blade Width

If you switch blade sizes often, don’t miss our detailed walkthrough, “Setting Bandsaw Guides for Different Blade Widths: A Reliable Adjustment Method.” This helpful guide explains how blade width affects tracking, how to position your side and thrust bearings correctly, and what to check before making a cut. It’s the ideal next read for anyone looking to achieve consistent, accurate results on every bandsaw setup.

Ideal for Curved Cuts

-

Micro-adjust side-bearing controls

-

Smooth, low-resistance roller action

-

Ability to position guides very close to the blade

-

Optimized for narrow blades

Looking for More Bandsaw Setup Guidance?

If you frequently swap between blade widths, consider reading our guide “How to Fine-Tune Bandsaw Guides for Different Blade Sizes.” It breaks down how blade width affects tracking, how to reset thrust and side bearings, and what to check before making your first cut.

Upgrading your Central Machinery 14″ band saw with roller-bearing guides is a simple way to enhance accuracy, reduce vibration, and extend blade life. Choosing a kit matched to your post size, blade range, and cutting style ensures the best performance and with periodic fine-tuning, your saw will stay reliable whether you’re resawing lumber or cutting tight curves.