Understanding Guide Setup Across Blade Width Changes

Many shops rely on a single bandsaw to perform both curved cutting and straight ripping by changing blade widths as needed. Because narrow and wide blades respond differently to tension and cutting force, guide positions must be adjusted each time a blade is replaced. Proper guide setup helps maintain blade stability, reduces unwanted movement, and supports consistent cutting results regardless of blade size.

Why Guide Settings Must Change with Blade Width

-

Blade position on the wheel crown varies by width

-

Narrow blades allow more flex during curved cuts

-

Wide blades resist side movement and require added support

-

Side guide spacing must align with blade thickness

-

Thrust bearing location shifts with blade load

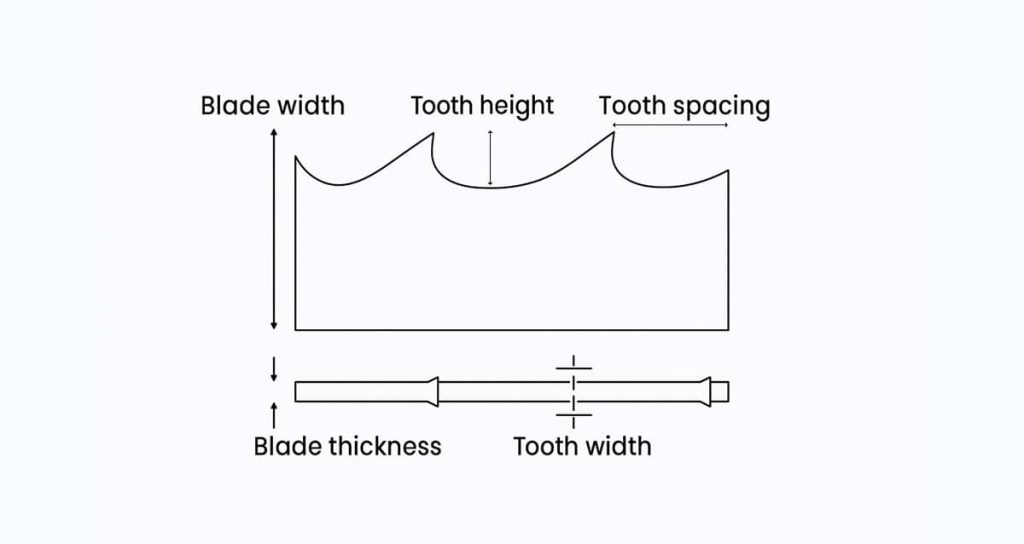

The Effect of Blade Construction on Guide Alignment

Each bandsaw blade differs in thickness, stiffness, and tooth configuration. When blade width changes, the blade follows a slightly different path through the guide system. If guides are left in their previous position, the blade may experience side pressure, uneven wear, or reduced cutting control. Adjusting the guides allows the blade to operate along its natural tracking path with proper support.

Tracking and Tensioning Before Guide Adjustment

Guide adjustment should always follow correct blade tracking and tensioning. After installing the blade, apply light tension and adjust tracking until the blade settles correctly on the wheels. Once the blade is centered, increase tension to the level specified for that blade width before making any guide adjustments.

Guide Adjustment Reference Overview

| Guide Component | Role | Adjustment Requirement |

|---|---|---|

| Side guides | Limit side movement | Match blade width and thickness |

| Thrust bearing | Restricts backward movement | Set just behind blade back |

| Upper guides | Support blade above material | Lower near the cut |

| Lower guides | Support blade below table | Match upper guide spacing |

Adjusting Thrust Bearings for Blade Changes

Thrust bearings should sit slightly behind the blade and engage only when cutting pressure is applied. When changing blade widths, reposition the bearing so it contacts the blade evenly without rotating constantly. Both upper and lower thrust bearings should maintain equal spacing to provide balanced blade support.

Setting Side Guides for Blade Stability

-

Position guides just behind the tooth gullets

-

Maintain minimal clearance to avoid constant contact

-

Match spacing between upper and lower guides

-

Align guides with the blade’s tracking position

-

Recheck spacing after adjusting blade tension

Checking Guide Post Height After Blade Replacement

Guide post height plays an important role in blade stability. Lowering the upper guide assembly close to the workpiece reduces blade movement, especially when using narrow blades or cutting taller material. Guide height should be reviewed each time blade width changes.

Confirming Setup Before Cutting

After adjustments are complete, rotate the wheels by hand to confirm smooth blade movement. Run the saw briefly without cutting to check for vibration or unusual noise. A test cut in scrap material helps verify tracking accuracy and guide alignment before returning to regular use.

Finding Documentation and Parts for Craftsman Bandsaws

For readers maintaining or servicing older equipment, we recommend reviewing “Sears Craftsman Bandsaws: Sourcing Manuals and Parts.” This article explains how to identify Craftsman bandsaw models, locate accurate manuals, and source compatible replacement parts to support proper setup and ongoing maintenance.

Practical Tips for Using Multiple Blade Widths

-

Record guide and tension settings for commonly used blades

-

Inspect guides regularly when making frequent adjustments

-

Keep bearings clean to ensure smooth operation

-

Check wheel tires for wear caused by narrow blades

-

Adjust both upper and lower guides with every blade change

Using multiple bandsaw blade widths on a single machine is effective when guide settings are adjusted correctly. Resetting blade tracking, side guides, thrust bearings, and guide height supports stable blade control and reliable cutting performance. With careful setup, a bandsaw can accommodate frequent blade changes while maintaining consistent accuracy.