Understanding Sears Craftsman Bandsaws

Sears Craftsman bandsaws have been widely used in home workshops, schools, and light industrial environments for many years. Their straightforward mechanical design allows these machines to remain functional well beyond their original production period. Access to the correct manuals and compatible replacement parts remains essential for maintaining safe operation and consistent cutting accuracy on Craftsman bandsaw models.

Why Manuals and Parts Matter for Craftsman Bandsaws

-

Helps identify proper setup and adjustment procedures

-

Provides accurate part numbers for replacement sourcing

-

Supports correct blade tension and tracking alignment

-

Reduces the risk of incorrect repairs

-

Assists with long-term maintenance planning

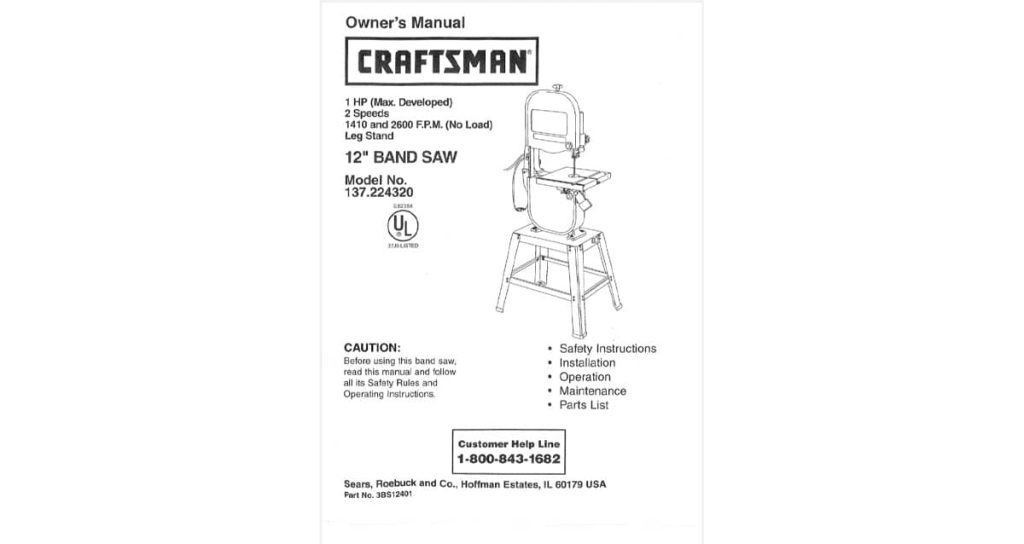

Identifying Your Craftsman Bandsaw Model

Before searching for manuals or replacement components, the bandsaw model number must be confirmed. Craftsman bandsaws typically use a numeric format that identifies both the manufacturer and the production series. This information is usually found on a metal plate or sticker attached to the frame, cabinet, or rear housing.

Where to Find Craftsman Bandsaw Manuals

Original Sears documentation is not always available through standard retail sources. Online manual archives have become a primary resource for owners seeking setup instructions, exploded diagrams, and adjustment guidance. Websites that specialize in bandsaw documentation often organize manuals by model number, saw size, and manufacturing period to simplify the search process.

Common Craftsman Bandsaw Models and Documentation Availability

| Bandsaw Size | Typical Model Series | Manual Type Available | Parts Diagram |

|---|---|---|---|

| 10-inch | 113.xxx | Owner manual | Yes |

| 12-inch | 113.xxx / 137.xxx | Owner + service | Yes |

| 14-inch | 113.xxx | Owner manual | Yes |

| Bench-top | 214.xxx | Owner manual | Limited |

Sourcing Replacement Parts for Craftsman Bandsaws

Replacement parts are commonly sourced using the original part numbers listed in Craftsman manuals. Aftermarket suppliers continue to offer blade guides, bearings, belts, switches, and wheel tires. Manuals play an important role in confirming compatibility, especially when multiple versions of the same bandsaw size exist.

Access a Complete Library of Bandsaw Manuals Online

Finding the correct documentation is easier when manuals are organized in one place. Bandsawmanuals.com provides access to a large collection of bandsaw manuals covering many brands, sizes, and production years. Whether you are looking for setup instructions, exploded diagrams, or maintenance guidance, our archive helps you locate the information needed to support proper adjustment, repairs, and long-term care of your bandsaw equipment.

Commonly Replaced Craftsman Bandsaw Components

-

Blade guide assemblies

-

Upper and lower wheel bearings

-

Drive belts and pulleys

-

Rubber or urethane wheel tires

-

Table trunnions and adjustment hardware

Using Exploded Diagrams Effectively

Exploded diagrams included in Craftsman bandsaw manuals provide a clear visual reference for assembly order and fastener placement. These diagrams help confirm how components fit together and reduce errors during disassembly or part replacement. Keeping a printed or digital copy available during repairs can simplify the process.

Tips for Matching Manuals to Older Craftsman Bandsaws

-

Match the complete model number, not just the saw size

-

Compare frame design and wheel layout with diagrams

-

Review revision notes within the manual

-

Confirm motor type and mounting configuration

-

Use diagrams to verify part compatibility

Overview of Bandsaw Guide System Options

For readers comparing different blade support methods, we recommend reviewing “Bandsaw Guide Systems Explained: Blocks or Bearings?” This article explains how guide blocks and bearing guides influence blade alignment, stability, and cutting control, helping users choose a guide system that fits their bandsaw setup and cutting requirements.

Long-Term Maintenance Planning with Proper Documentation

Access to the correct Craftsman bandsaw manual supports routine inspections and planned maintenance. Manuals outline lubrication points, alignment checks, and adjustment procedures that help maintain cutting consistency and reduce mechanical wear over time.

Sears Craftsman bandsaws remain serviceable when supported by accurate manuals and reliable parts sourcing. By confirming model numbers, referencing exploded diagrams, and using dependable documentation sources, owners can maintain these machines with confidence. Bandsawmanuals.com provides organized access to Craftsman bandsaw manuals and schematics, supporting continued operation of older equipment.