Understanding the Value of a Pro Tech Bandsaw

Pro Tech bandsaws have long been recognized for their balance of affordability and function. Whether you’re working with wood, metal, or plastic, these machines provide accessible precision and steady performance in home shops and small-scale professional settings. If you’re looking to get consistent results without stretching your budget, Pro Tech models are a reliable place to start.

Why Choose the Pro Tech 3203?

- Accurate, steady cutting across materials

- Easy-to-use adjustments for tension and alignment

- Compatible with different blade types

- Built for wood, plastic, and light metal projects

- Designed for smaller workspaces with limited power needs

Performance That Matches Everyday Needs

One of the strengths of the Pro Tech 3203 is its ease of use. For users who don’t require commercial-level machines but still need a capable saw, it delivers solid cutting results with minimal complexity. Its straightforward operation and consistent performance make it a practical choice for anyone working with a variety of material types.

Built for Simplicity and Control

The Pro Tech 3203 features core elements that prioritize user control. An adjustable blade guard helps maintain clean lines, while a simple tensioning system lets you fine-tune the blade position as needed. It’s not just about what this saw can do—it’s how efficiently it lets you do it.

Pro Tech 3203 Bandsaw – Key Specs Overview

| Feature | Description |

|---|---|

| Motor Type | Variable speed |

| Blade Compatibility | 3/16″ to 1″ wide |

| Material Compatibility | Wood, metal, plastic |

| Frame Style | Compact, vertical |

| Common Use | DIY projects, small workshops |

Explore More Options for Your Pro Tech Bandsaw

Choosing the right blade for your project can make a significant difference. From fine-tooth options for clean wood cuts to aggressive teeth for plastic or soft metals, matching your blade to your job gives you cleaner results and extends blade life.

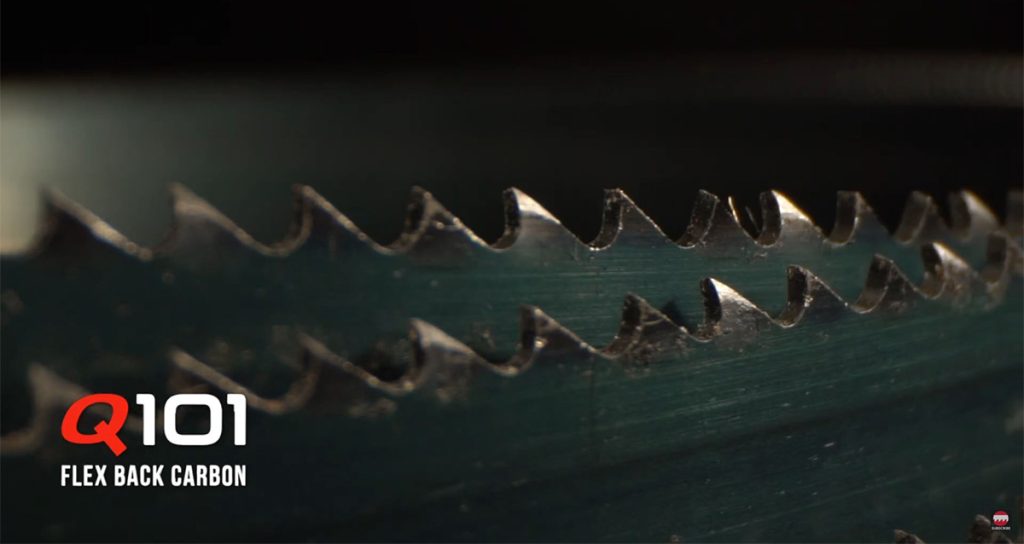

Cutting with Confidence: Qsaw 101 Flex Back Carbon Blades

For woodworking enthusiasts and light-duty metalworkers, the Qsaw 101 Flex Back Carbon Band Saw Blade is a versatile and cost-effective choice. Whether you’re resawing lumber on a stationary mill or doing fine scroll work in a home shop, the Q101 adapts with precision. With tooth pitches ranging from coarse 3–6 TPI for wood to fine 8–18 TPI for plastics and soft metals, this blade excels across applications. Its spring-tempered design adds strength and rigidity, while the heat-treated teeth maintain sharpness for clean, accurate cuts. The Qsaw 101 is a flexible, everyday solution that delivers reliable results without driving up cost per cut.

Strong and Steady: Qsaw 201 Hard Back Carbon Blades

When your cutting jobs demand extra control and straighter lines, the Qsaw 201 Hard Back Carbon Band Saw Blade is up to the task. Originally developed for steel, it handles wood, aluminum, and mild steels with ease. Available in 2–24 TPI options, the blade is built from a single piece of high-carbon steel with a spring-tempered back and individually hardened teeth. That construction gives it added rigidity for heavier feed rates and increased cutting accuracy. Whether you’re operating a vertical bandsaw for contour cuts or a horizontal machine for cutoff work, the Qsaw 201 offers long-term durability and sharp, clean results across a range of materials.

Keeping Your Bandsaw Working Like New

Ongoing maintenance ensures the Pro Tech 3203 stays in good shape. Cleaning dust and debris from the housing, tensioners, and blade path will reduce wear over time. Basic upkeep goes a long way toward maintaining reliable cuts and avoiding early part failure.

Maintenance Tips for Long-Term Use

- Clean the blade area after every use

- Check tension regularly for proper tracking

- Use a light machine oil on moving parts

- Clear vent holes to avoid motor heat issues

- Replace blades when signs of dulling appear

Safety Considerations While Operating

Even with smaller saws like the 3203, safety should never be overlooked. Always secure your material before cutting and never force the blade. Wear appropriate eye and hand protection to avoid preventable accidents in the shop.

Recommended Safety Gear Checklist

- Safety glasses

- Cut-resistant gloves

- Hearing protection

- Dust mask (especially for wood)

- Anti-slip footwear

Learn More About Carolina HD Series Bandsaws

If you’re interested in dependable cutting solutions beyond the Pro Tech lineup, be sure to read our article “Carolina Bandsaws: Exploring the Classic HD Series for Reliable Cutting.” This detailed overview dives into the design and performance of the classic HD series, a favorite among workshops for its rugged build and long-term reliability. Whether you’re comparing features or looking to upgrade, it’s a helpful read for any bandsaw user.

The Pro Tech 3203 is a reliable addition to any workspace focused on everyday cutting needs. With proper care and the right blades, this model offers long-term value in a compact, user-friendly package. Whether you’re tackling weekend woodworking or small fabrication jobs, it’s built to meet the demand without excess complication.