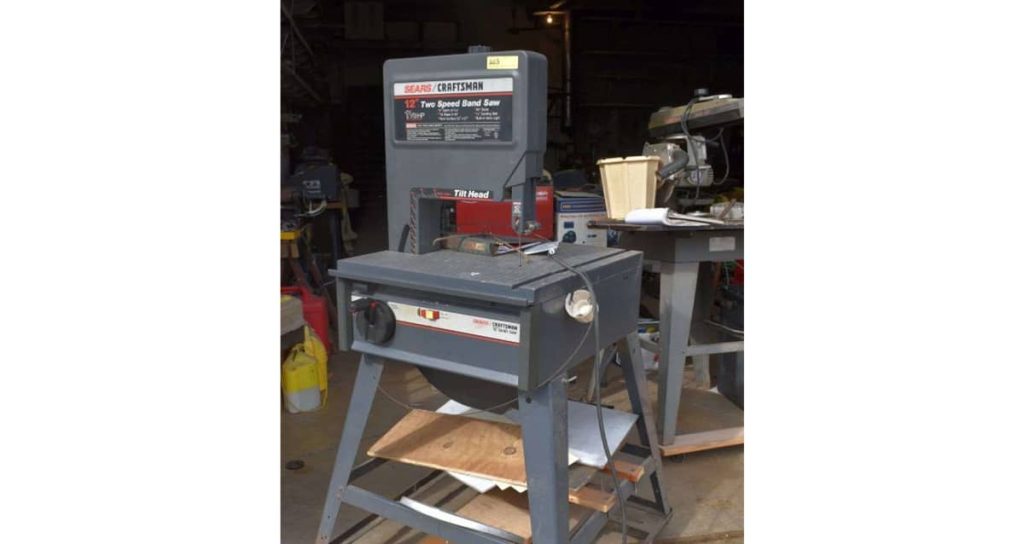

The Craftsman 12″ bandsaw is a mid-range machine that has become popular with DIYers and small workshops. Thanks to its 12-inch throat capacity, it can perform tasks like resawing, ripping, and curve cutting. Many units include adjustable guides, a stable frame, and a motor in the 1 HP range.

It’s well-regarded for being easy to operate and dependable, even though older models may lack advanced features like dust collection. Once properly tuned, it delivers reliable performance for a wide range of woodworking tasks.

To get the most out of it, you’ll need to know the correct blade sizes and how to select the right type for your projects.

Blade Length: What You Need to Know

Most Craftsman 12″ bandsaws such as models 9HT2433N and 22432 run on 80″ blades, which support widths from 1/8″ to 1/2″.

Some models differ: the 22400 uses 89½″ blades, and the 22412 takes 91″ blades.

Always confirm your model number before ordering blades to ensure the right fit.

Blade Width: Match to the Task

1/8″–3/8″ blades are best for tight curves or detail work.

1/2″ blades are versatile for general and straight cuts.

Blades wider than 1/2″ are usually not suitable for Craftsman 12″ saws.

TPI (Teeth Per Inch): Balance Speed and Finish

3–6 TPI provides quick cuts with a rougher finish, suited for thick stock.

6–10 TPI offers a good balance for most woodworking.

10–14+ TPI delivers smoother, precise cuts on thinner materials.

Sawblade.com offers a speed and feed chart and instructional videos to help choose the right TPI for different materials.

Blade Types and Tooth Designs

| Blade Type | Material | Best For |

|---|---|---|

| Carbon Steel | Low-cost, dulls faster | Light projects, wood |

| Bi-Metal | Durable, long-lasting edge | Frequent use, hardwoods, light metals |

| Carbide-Tipped | Extremely tough | Industrial, dense or abrasive stock |

Tooth designs include:

Regular – Standard use across wood types

Skip-tooth – Helps prevent clogging, ideal for softwoods

Hook-tooth – Aggressive cutting, suited for thicker materials

Popular Qsaw Options

Sawblade.com custom-makes blades for Craftsman saws. Two recommended choices include:

Qsaw 101 FlexBack – Flexible carbon blade designed for fine detail and curve cutting, available in coarse or fine TPI ranges.

Qsaw 201 HardBack – Heat-treated teeth and rigid back for resawing and heavy-duty straight cuts, available in coarse and fine tooth options.

Quick Selection Chart

| Task | Recommended Blade | Why |

|---|---|---|

| Curves and scroll cutting | Qsaw 101 FlexBack | Flexible and precise |

| Straight cuts and resawing | Qsaw 201 HardBack | Rigid and durable |

Mistakes to Avoid

Using the wrong length blade can result in poor tension and unsafe operation.

Blades wider than 1/2″ may not align properly.

Choosing the wrong TPI can cause rough edges or slow cuts.

Cheap carbon blades are not ideal for heavy use.

Ignoring blade setup often leads to poor tracking and reduced blade life.

Best Blade for Overall Use

For most Craftsman 12″ bandsaw projects, an 80″ × 1/2″ × 6–10 TPI bi-metal blade gives the best mix of durability, clean cuts, and versatility.

Learn How to Fine-Tune Your Bandsaw for Better Accuracy

If your cuts aren’t as straight as you’d like, the problem may lie in your guide bearings. With the right adjustments, you can greatly improve accuracy and extend blade life. For a practical walkthrough, check out our article “Adjusting Bandsaw Guide Bearings: A Clear Guide for Better Accuracy.”

Getting the right bandsaw blade comes down to understanding your Craftsman 12” model and the materials you’re working with. Avoiding the wrong fit and selecting a blade designed for your specific needs will keep your saw running smoothly and your cuts precise for years to come.