Recognizing Early Blade Wear on Bandsaws

A bandsaw blade is expected to provide consistent cutting results across multiple operations, particularly during straight cuts and resawing tasks. When a blade loses sharpness sooner than anticipated, the issue is usually linked to operating conditions or machine setup. Blade wear commonly results from material contamination, feed technique, or mechanical alignment. Identifying these factors supports steadier cutting results and improved blade longevity.

Cutting Stock Containing Abrasive Particles

Material condition plays a major role in blade wear. Abrasive particles significantly reduce tooth life.

-

Sand and soil wear tooth edges quickly

-

Reclaimed boards may contain embedded grit or residue

-

Outdoor-stored lumber often collects fine debris

-

Boards that contact the ground transfer abrasive material directly into the cut

Cleaning stock before cutting and using older blades for uncertain material helps limit avoidable tooth damage.

Insufficient Forward Feed Pressure

Feeding stock too slowly causes teeth to rub rather than cut efficiently. This increases heat buildup and promotes resin accumulation on the blade. Applying steady, controlled feed pressure allows teeth to clear chips effectively and maintain consistent cutting behavior.

Tooth Pitch Mismatch With Material Thickness

Selecting the correct tooth pitch is essential for managing wear. Blades with excessive tooth density on thick stock restrict chip clearance, while low tooth counts on thin material overload individual teeth. Matching teeth-per-inch to material thickness promotes uniform engagement and controlled cutting.

Blade Tension Setup Errors

Blade tension influences tracking stability and tooth loading. Low tension permits blade deflection, while excessive tension places added stress on both the blade body and tooth edges. Balanced tension supports straight tracking and more even wear patterns.

Blade Width and Curve Radius Guide

| Blade Width | Minimum Curve Radius |

|---|---|

| 1/8″ | 3/16″ |

| 3/16″ | 5/16″ |

| 1/4″ | 5/8″ |

| 3/8″ | 1-1/2″ |

| 1/2″ | 2-1/2″ |

| 3/4″ | 5″ |

Using a blade that exceeds the recommended curve radius increases side loading and accelerates wear.

Resin Accumulation on the Blade

Resin-heavy woods can leave buildup on the blade body and teeth. This buildup traps heat and increases resistance during cutting. Regular cleaning with suitable solvents helps maintain cutting efficiency and reduces heat-related wear.

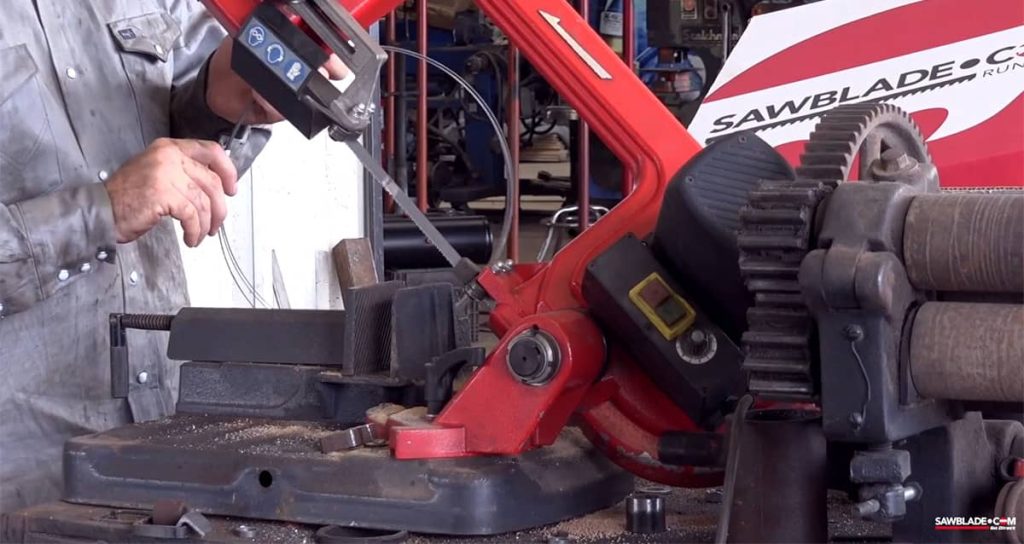

Guide and Bearing Adjustment Problems

Incorrect guide positioning introduces unnecessary friction. Side guides should sit slightly away from the blade, while thrust bearings should engage only under cutting pressure. Proper alignment reduces blade twisting and uneven tooth loading.

Effect of Blade Construction Quality

Manufacturing quality has a direct impact on blade durability.

-

Softer steel dulls rapidly

-

Uneven tooth set creates inconsistent loading

-

Poor weld quality causes vibration

-

Roughly finished teeth increase friction

Blades produced with consistent materials and accurate tooth geometry support steadier cutting over time.

Wheel Alignment and Tracking Issues

Misaligned wheels cause the blade to rub laterally against guides and tires. This side contact reduces tooth set and accelerates fatigue. Correct tracking places the blade on the tire crown and limits sideways movement.

Controlling Heat During Extended Cutting

Extended cutting sessions generate heat that reduces tooth hardness. Maintaining consistent feed pressure, cleaning buildup, and allowing brief cooling intervals between passes helps manage thermal stress during demanding cuts.

Explore the Construction and Components of Ramco Bandsaws

Understanding how a bandsaw is built can help with both operation and long-term upkeep. The article “Ramco Bandsaws: Examining Build Quality and Core Components” takes a closer look at frame design, blade drive systems, guide assemblies, and commonly serviced parts. It’s a useful read for anyone evaluating Ramco bandsaws or planning maintenance and part replacement.

Typical Bandsaw Blade Usage Expectations

-

Softwood cutting: several hours of operation

-

Hardwood cutting: shorter usage periods

-

Heavy resawing: limited time with economy blades

-

Higher-grade blades: longer service under similar conditions

Rapid dulling usually indicates setup or material-related issues.

Bandsaw blades are consumable items, but frequent replacement is not inevitable. Proper blade selection, material preparation, guide adjustment, and feed control all contribute to extended blade use. Addressing common wear factors allows operators to maintain steady cutting results and reduce unnecessary blade changes.