Why Upgrade Your Existing Bandsaw Instead of Replacing It? If you own an older bandsaw, particularly a 14-inch cast iron unit from brands like Delta, Jet, Powermatic, or Craftsman, your machine likely has a rigid frame and reliable mechanical structure. These saws were designed … [Read more...]

Marvel PA13 Guide: Manual, Blade Size, Parts, and Common Fixes

Overview of the PA13 Vertical Bandsaw The PA13 vertical bandsaw is commonly used in workshop settings to cut structural materials such as metal. This machine supports controlled cutting operations across fabrication and maintenance tasks. Understanding setup procedures, blade … [Read more...]

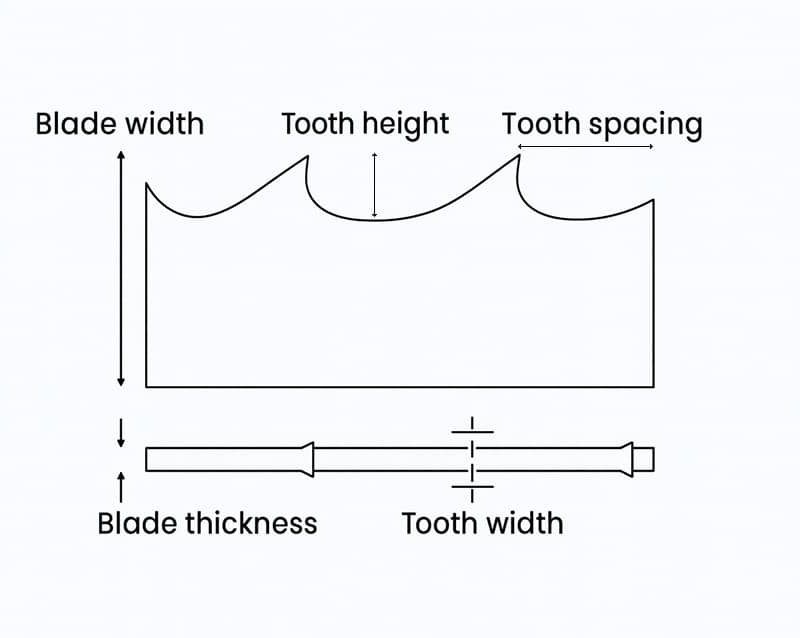

Choosing the Best Bandsaw Blade Width for Accurate Cutting

The Role of Bandsaw Blade Width in Cutting Performance Using the correct bandsaw blade width plays an important role in producing clean and controlled cuts. Blade width influences curve capability, straight cut stability, resaw efficiency, and overall cutting accuracy. Selecting … [Read more...]

Delta BS100 Guide: Manual, Blade Size, Parts, and Common Fixes

Overview of the Delta BS100 Bandsaw The Delta BS100 is a compact benchtop bandsaw commonly used for light cutting tasks in home shops and small workshops. Its simple mechanical layout makes it suitable for basic woodworking and hobby projects. Understanding how the saw is … [Read more...]

Bandsaw Yearly Care Guide: Maintain Reliable and Smooth Cuts

Why Yearly Bandsaw Care Makes a Difference A bandsaw can perform consistently for many shop applications, but results may decline without scheduled attention. Dust accumulation, aging tires, dull blades, and small alignment changes can affect cut accuracy and motor operation. … [Read more...]

Delta 28-206 Guide: Manual, Blade Size, Parts, and Common Fixes

Overview of the Delta 28-206 Bandsaw The Delta 28-206 is a floor-standing bandsaw commonly used in small shops and home workshops. Produced by Delta Machinery, this model features a cast-iron frame and a straightforward mechanical layout. Understanding its specifications and … [Read more...]

Simple Method to Verify Bandsaw Wheel Alignment Fast

Why Bandsaw Wheel Position Affects Cutting Results The position of a bandsaw’s wheels has a direct impact on how the blade behaves during cutting. When the upper and lower wheels are not aligned in the same plane, problems such as blade drift, uneven cut lines, vibration, and … [Read more...]

Bandsaw Blades Wearing Out Early? Key Reasons and Corrective Actions

Recognizing Early Blade Wear on Bandsaws A bandsaw blade is expected to provide consistent cutting results across multiple operations, particularly during straight cuts and resawing tasks. When a blade loses sharpness sooner than anticipated, the issue is usually linked to … [Read more...]

Ramco Bandsaws: Examining Build Quality and Core Components

Overview of Ramco Bandsaws Ramco bandsaws are widely used in fabrication shops where steady straight cutting and mechanical reliability are required. Their designs typically emphasize rigid construction, controlled blade movement, and parts that can be serviced over time. These … [Read more...]

Installing a Bearing Guide Kit on a Bandsaw for Improved Cut Consistency

How a Bearing Guide Kit Improves Bandsaw Operation A bearing guide kit replaces original guide blocks or worn factory bearings with a more controlled bearing-supported system. Many older bandsaws from manufacturers such as Delta, Jet, and Craftsman use stock guide assemblies … [Read more...]

- 1

- 2

- 3

- …

- 11

- Next Page »