Overview of the Delta BS100 Bandsaw

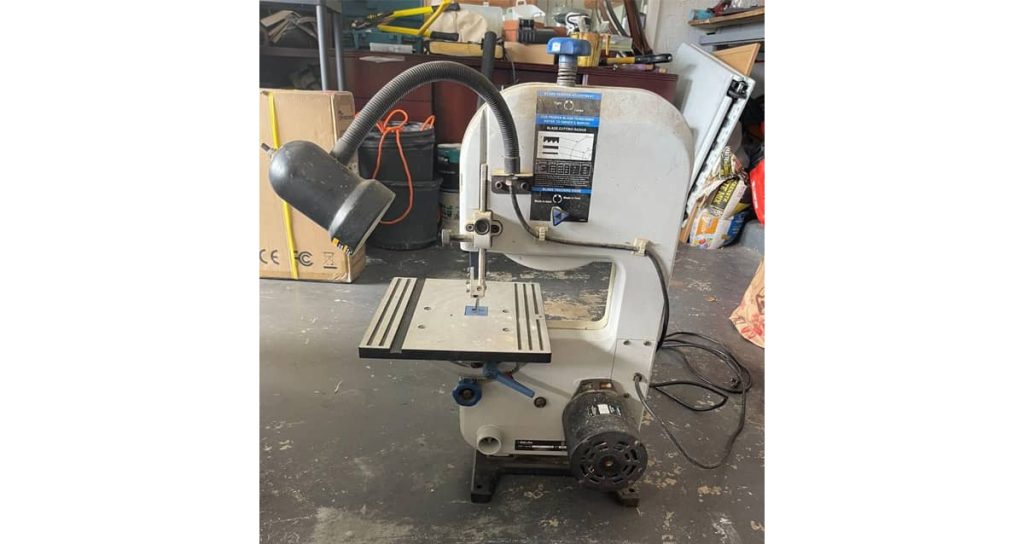

The Delta BS100 is a compact benchtop bandsaw commonly used for light cutting tasks in home shops and small workshops. Its simple mechanical layout makes it suitable for basic woodworking and hobby projects. Understanding how the saw is configured and maintained helps support steady cutting results over time.

What the Delta BS100 Manual Includes

The Delta BS100 manual serves as a practical reference for setup, adjustment, and routine operation, including:

-

Initial assembly and bench mounting guidance

-

Blade installation and tracking adjustment procedures

-

Blade tension setup instructions

-

Safety notices and operating limits

-

Basic maintenance and inspection guidelines

Using the manual during setup and adjustments helps limit errors and supports reliable operation.

Blade Size Considerations for the Delta BS100

Blade size plays a major role in how the Delta BS100 performs during cuts. Selecting the correct blade length and width helps maintain tracking stability and reduces unnecessary load on internal components. Incorrect blade sizing may lead to uneven cuts, slipping, or tracking problems during use.

Understanding the Delta BS100 Blade Length

The Delta BS100 typically uses a 62-inch bandsaw blade. This length is designed to match the saw’s wheel spacing and tension range. Staying within the recommended blade size supports stable tracking and consistent cutting behavior.

Delta BS100 Specifications at a Glance

| Specification | Details |

|---|---|

| Blade Length | 62 inches |

| Blade Width Range | 1/8″ to 1/2″ |

| Frame Style | Benchtop |

| Wheel Material | Aluminum |

| Primary Use | Light woodworking |

Parts That Commonly Wear Over Time

Like most small bandsaws, the Delta BS100 includes parts that gradually wear with regular use. Tires, blade guides, thrust bearings, and drive belts should be inspected periodically. Early identification of wear helps prevent cutting issues and unnecessary downtime.

Access Free Bandsaw Manuals Online

If you’re looking for setup instructions, specifications, or service references, visit BandsawManuals. The site provides free access to a large collection of bandsaw manuals, making it easier to find model-specific information for maintenance, adjustments, and proper operation.

Typical Issues and Corrective Actions

-

Blade drifting caused by guide misalignment

-

Vibration linked to worn tires or loose fasteners

-

Blade slipping due to improper tension settings

-

Tracking difficulty related to wheel alignment

Addressing these conditions early helps maintain predictable cutting performance.

Keeping the Delta BS100 Operating Smoothly

Routine cleaning and inspection help support consistent operation. Removing sawdust from the wheel area, checking blade condition, and confirming guide alignment can extend service intervals. Making small adjustments on a regular basis reduces the chance of more serious mechanical concerns.

When Parts Should Be Adjusted or Replaced

-

Tires show cracking or uneven wear

-

Guides no longer maintain blade position

-

Belt shows glazing or visible deterioration

-

Bearings produce unusual noise during operation

Responding to these indicators early helps preserve cutting accuracy.

Review a Yearly Bandsaw Care Routine

Keeping a bandsaw operating smoothly requires regular attention throughout the year. To see a clear breakdown of routine checks and adjustments that support steady cutting results, read “Bandsaw Yearly Care Guide: Maintain Reliable and Smooth Cuts.” This related article outlines practical steps that help maintain consistent performance over time.

Finding Replacement Parts for the Delta BS100

Replacement parts for the Delta BS100 are commonly available through online retailers and aftermarket suppliers. Matching blade dimensions and part specifications helps ensure proper fit and restores original operating behavior.

Maintaining the Delta BS100 involves using the correct blade size, referencing the manual when making adjustments, and monitoring components that experience wear. With routine inspections and simple upkeep, this bandsaw can continue delivering dependable cutting performance for small shop tasks and hobby applications.