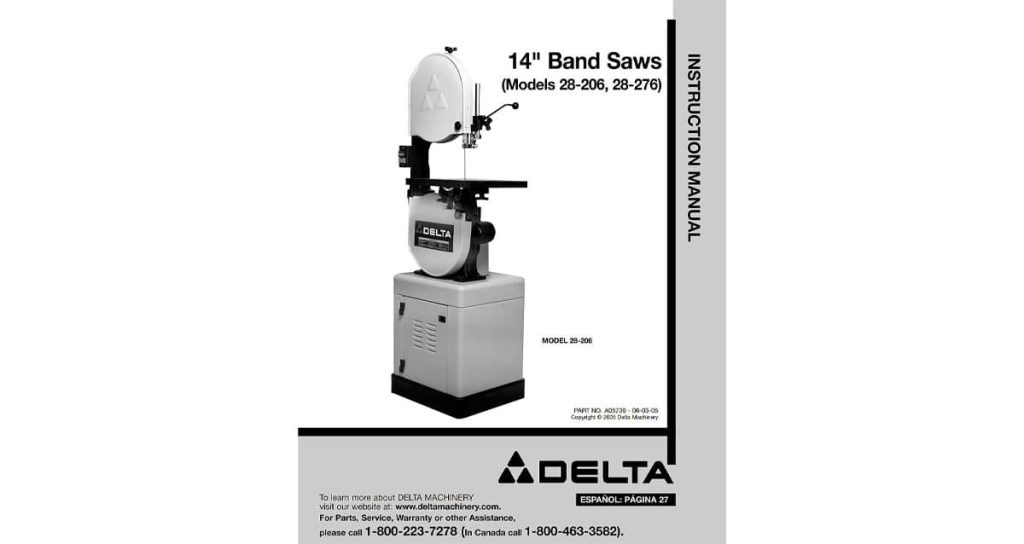

Overview of the Delta 28-206 Bandsaw

The Delta 28-206 is a floor-standing bandsaw commonly used in small shops and home workshops. Produced by Delta Machinery, this model features a cast-iron frame and a straightforward mechanical layout. Understanding its specifications and service points helps owners keep the saw operating smoothly over time.

What the Delta 28-206 Manual Covers

-

Assembly and initial setup instructions

-

Blade installation and tracking adjustment

-

Tensioning and guide alignment procedures

-

Electrical components and switch layout

-

Routine service and maintenance guidance

Blade Size and Compatibility

Blade size plays an important role in how the Delta 28-206 performs. Using the correct blade length and width helps maintain stable tracking and accurate cuts. A blade that matches the saw’s design also reduces strain on the wheels, guides, and bearings during operation.

Understanding the Delta 28-206 Blade Length

The Delta 28-206 typically uses a 93½-inch bandsaw blade. This length supports a range of blade widths suitable for straight cuts and curved work. Staying within the recommended size range helps prevent tensioning issues and uneven blade tracking.

Key Specifications at a Glance

| Specification | Details |

|---|---|

| Blade Length | 93½ inches |

| Maximum Blade Width | Up to ¾ inch |

| Wheel Material | Cast iron |

| Frame Style | Floor-standing |

| Intended Use | Wood cutting applications |

Common Parts That Wear Over Time

Like most bandsaws, the Delta 28-206 includes components that may require attention after extended use. Tires, guide blocks, thrust bearings, and belts can gradually wear. Regular inspection helps identify these issues before they affect cutting accuracy.

Typical Issues and Fixes

-

Blade drifting during cuts caused by guide misalignment

-

Excess vibration linked to worn tires or improper belt tension

-

Blade slipping related to incorrect tension settings

-

Tracking difficulty associated with wheel alignment

Keeping the Bandsaw Running Smoothly

Regular upkeep helps extend the service life of the Delta 28-206. Removing sawdust from wheel housings, checking guide alignment, and monitoring blade condition all support consistent operation. Small adjustments made on a routine basis can help prevent larger mechanical issues.

When to Replace or Adjust Parts

-

Tires show cracking or uneven wear

-

Guides no longer maintain blade position

-

Belt shows glazing or slippage

-

Bearings produce noticeable noise during operation

Addressing these signs early helps maintain steady cutting performance.

Learn a Fast Way to Check Bandsaw Wheel Alignment

Proper wheel alignment supports smooth blade tracking and consistent cutting results. To see a clear method for verifying alignment using basic shop tools, take a moment to read our related article “Simple Method to Verify Bandsaw Wheel Alignment Fast.” It explains how to identify alignment issues quickly before they affect cut quality.

Sourcing Replacement Parts

Replacement parts for the Delta 28-206 are widely available through aftermarket suppliers and parts distributors. Matching part numbers and measurements ensures proper fit and helps restore original operating conditions.

Maintaining a Delta 28-206 bandsaw involves understanding the manual, using the correct blade size, and addressing common wear items as they appear. With regular inspections and proper adjustments, this bandsaw can continue to deliver reliable cutting results across a wide range of shop tasks.