Why Blade Width Changes Require New Guide Settings

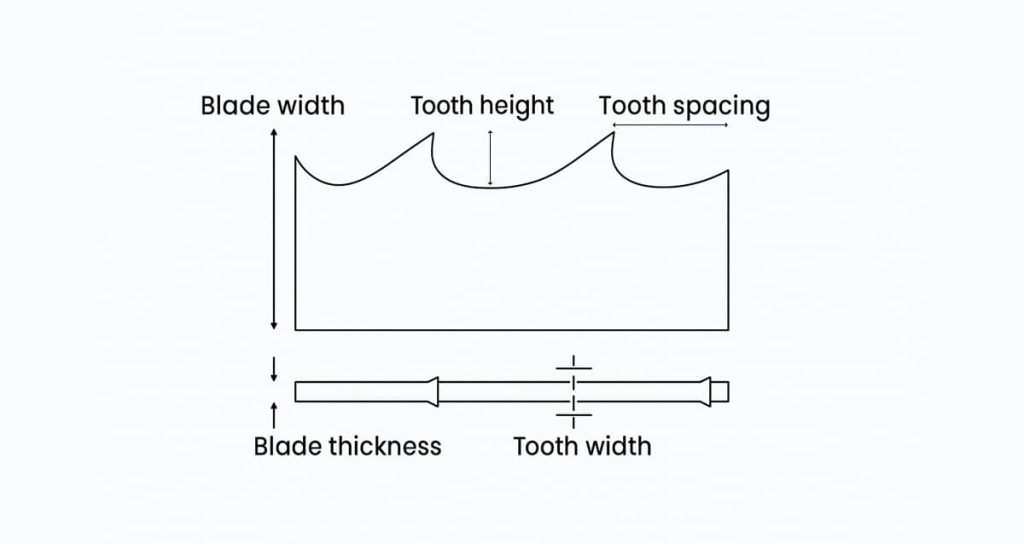

Every time you switch from a narrow blade used for tight curves to a wider blade designed for straight cuts, the behavior of the blade changes. Blade width affects how the blade rides on the wheel crown, how stiff it feels under tension, and how easily it twists. Because of this, your guides must be readjusted to match the new blade path so your saw stays accurate and runs smoothly.

What Changes When You Install Another Blade

• Blade position on the crown of the upper wheel

• Amount of required tension

• Lateral flexibility

• Tooth set shape

• Tracking dependability

• Curve cutting ability

• Twist resistance

• Sensitivity to side support

Start by Centering the Blade

Before any guide adjustment, the blade needs to track correctly on the wheels. Install the blade, apply light tension, and rotate the wheel by hand. Use the tracking control to position the gullets near the center of the upper wheel crown. After the blade settles into position, increase tension to the proper level for its width. This provides a steady foundation for all later adjustments.

Setting the Thrust Bearings Correctly

Thrust bearings keep the blade from moving backward during a cut. Position them slightly behind the blade so they sit close but do not touch during idle running. Adjust both upper and lower thrust bearings so they match each other. Keep the gullets clear so the teeth do not come into contact with the bearing face.

Positioning the Side Guides

Side guides help prevent twist and lateral movement. Different guide styles require slightly different adjustment methods. Correct spacing ensures the blade stays steady during straight cuts or curved cuts.

Side Guide Types and Their Setup

| Feature | Bearing Guides | Cool Blocks | Ceramic Guides |

|---|---|---|---|

| Blade Contact | Small clearance | Light contact allowed | Light contact allowed |

| Position | Behind gullets | Behind gullets | Behind gullets |

| Heat Control | Very good | Good | Very good |

| Best For | Thin to mid blades | Thin blades | All blade sizes |

| Maintenance | Needs cleaning | Very low | Very low |

Adjust the Guide Post for Better Stability

After setting the guides, lower the upper guide post so it sits near the workpiece. A short distance reduces blade movement under load and improves accuracy. This helps both wide blades used for resawing and narrow blades used for shaping curves.

Useful Tips for Faster Switching Between Blades

• Keep notes on settings for each blade size

• Make sure bearings spin freely

• Confirm block guides are not pressing too firmly

• Track your tension settings for easy repeatability

• Remove sawdust from guide housings

• Check wheel tires if narrow blades leave grooves

Frequent Alignment Mistakes

Some common issues can affect cut quality if not addressed. Avoid adjusting your guides too early or skipping steps that affect the lower guide assembly.

Problems to Avoid

• Adjusting guides before setting tension

• Closing the guides too tightly

• Ignoring the lower guides

• Using a dull blade during alignment

• Allowing thrust bearings to run constantly

• Forgetting to check fence position after a blade change

When an Upgrade Makes Blade Changes Easier

If tuning your factory guides is frustrating or slow, an upgraded guide system may improve accuracy and speed. Many aftermarket guides provide smoother adjustments and better support for a range of blade sizes.

Learn How to Improve Guide Accuracy With a Simple Adjustment

If you want your bandsaw to track straighter and cut more consistently, take a moment to read “Eccentric Post Setup Made Simple: Improving Bandsaw Guide Accuracy.” That article explains how a properly adjusted eccentric post sharpens guide positioning, reduces drift, and helps your blade stay stable during demanding cuts. It’s a valuable resource for anyone tuning their saw for smoother, more predictable performance.

Guide Upgrade Choices

• Bearing-style guide kits

• Ceramic guide systems

• Replacement thrust bearings

• Quick-adjust housings

• Conversion kits for Delta, Jet, Rikon, and Grizzly saws

Running multiple blade widths adds flexibility to your bandsaw, but each blade needs its own alignment to perform well. By setting the thrust bearings, positioning the side guides, and adjusting guide post height, your saw will cut straighter and maintain better tracking. A short setup routine helps protect your blades and makes every cut more predictable.