Why Your Rockwell 28-200 Bandsaw Manual Matters

Operating a Rockwell 28-200 bandsaw efficiently requires more than just experience it demands a clear understanding of its specifications, maintenance procedures, and troubleshooting techniques. The manual serves as an essential reference, ensuring your machine operates at peak performance while minimizing downtime due to unexpected issues.

Key Benefits of Using the Rockwell 28-200 Bandsaw Manual

- Detailed Maintenance Instructions – Prevent wear and prolong the lifespan of your saw.

- Troubleshooting Guidance – Quickly diagnose and fix common operational issues.

- Blade Adjustment Tips – Ensure precise cuts with proper tension and alignment.

- Safety Precautions – Follow guidelines to prevent accidents and maintain a secure workspace.

- Optimal Performance Settings – Adjust speed and feed rates based on material type.

Understanding the Rockwell 28-200 Bandsaw’s Features

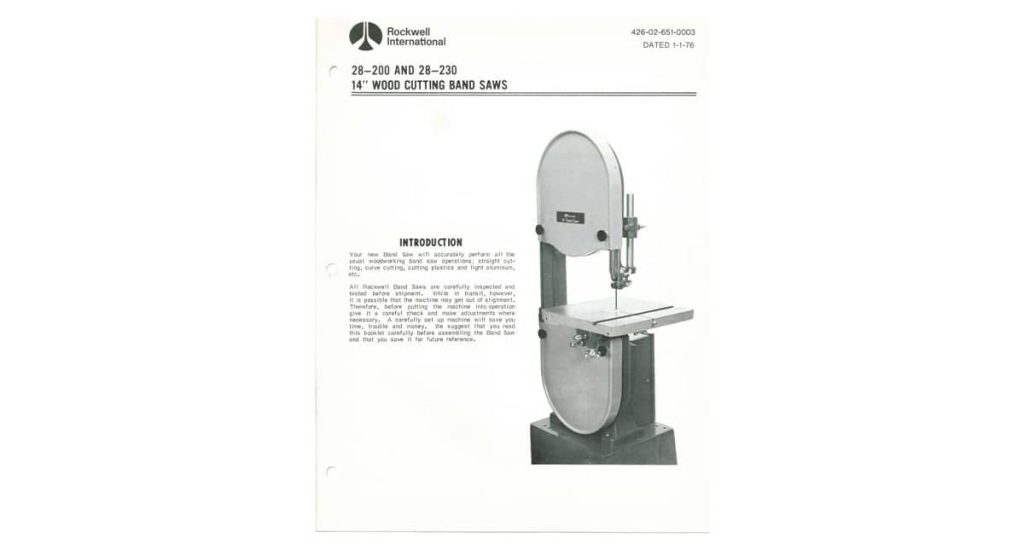

The Rockwell 28-200 is a widely used bandsaw known for its durability and precision. Its cast-iron frame offers stability, while its adjustable speed settings allow users to work with various materials. The tilting table provides versatility for making angled cuts, and its quick-change blade system ensures efficiency when switching between different tasks.

Routine Maintenance for Extended Performance

Regular upkeep is essential to keep your bandsaw running smoothly. Cleaning sawdust buildup, inspecting blade guides, and applying lubricant to moving parts are all simple steps that can significantly extend the machine’s lifespan. Keeping tension properly adjusted and ensuring the motor is running at the correct speed will also prevent unnecessary strain on components.

Specifications of the Rockwell 28-200 Bandsaw

Understanding the technical details of your Rockwell 28-200 can help you select the right blades, perform accurate maintenance, and troubleshoot potential problems.

| Feature | Specification |

|---|---|

| Motor Power | ½ HP – 1 HP |

| Blade Length | 93 ½ inches |

| Blade Width | ⅛″ to ½″ |

| Cutting Capacity | 12″ width |

| Table Dimensions | 14″ x 14″ |

| Table Tilt | 0° to 45° |

| Speed Options | Variable |

| Frame Construction | Cast Iron |

Common Issues and How to Fix Them

Even a well-maintained Rockwell 28-200 can encounter operational problems. If the blade drifts while cutting, check the tracking adjustment and ensure the guide bearings are aligned. For excessive vibration, inspect the wheel balance and confirm that the blade is tensioned correctly. Slow cutting performance often indicates a dull blade that needs replacement.

Essential Accessories for the Rockwell 28-200

- High-quality bandsaw blades – Match the blade type to the material for clean cuts.

- Blade guide upgrades – Improve stability and accuracy.

- LED work lights – Enhance visibility for detailed work.

- Dust collection system – Minimize debris buildup and improve workspace cleanliness.

- Fence system – Assist with straight cuts and repeatable accuracy.

Finding a Rockwell 28-200 Bandsaw Manual Online

At BandsawManuals.com, we specialize in providing manuals for all your bandsaw needs, including the Rockwell 28-200. Instead of searching through manufacturer websites or tool forums, you can quickly access a free, downloadable PDF directly from our platform. Whether you need troubleshooting guidance, maintenance tips, or setup instructions, keeping a digital or printed copy ensures you have essential information readily available whenever needed.

Safety Tips for Operating Your Rockwell 28-200

- Always wear protective eyewear and gloves while operating the saw.

- Ensure the blade is properly tensioned before making cuts.

- Keep hands a safe distance from the cutting area.

- Regularly inspect power cords and motor connections for wear.

- Disconnect power before performing maintenance or blade changes.

Keeping Your Bandsaw in Top Shape

Regular maintenance is key to ensuring your bandsaw operates efficiently, but knowing where to find and replace worn-out parts is just as important. If you own a Marvel Series 8 Mark II, having the right replacement components can prevent downtime and extend the lifespan of your machine. To learn more about identifying, sourcing, and installing essential parts, check out our detailed guide: How to Find and Replace Parts for the Marvel Series 8 Mark II.

Final Thoughts on the Rockwell 28-200 Bandsaw

The Rockwell 28-200 remains a dependable choice for woodworkers and metal fabricators alike. By following regular maintenance procedures, using the correct blades, and referencing the bandsaw manual when necessary, you can keep your saw operating smoothly for years to come. Whether you’re troubleshooting an issue or optimizing performance, having a clear understanding of your machine ensures consistent and precise cutting results.