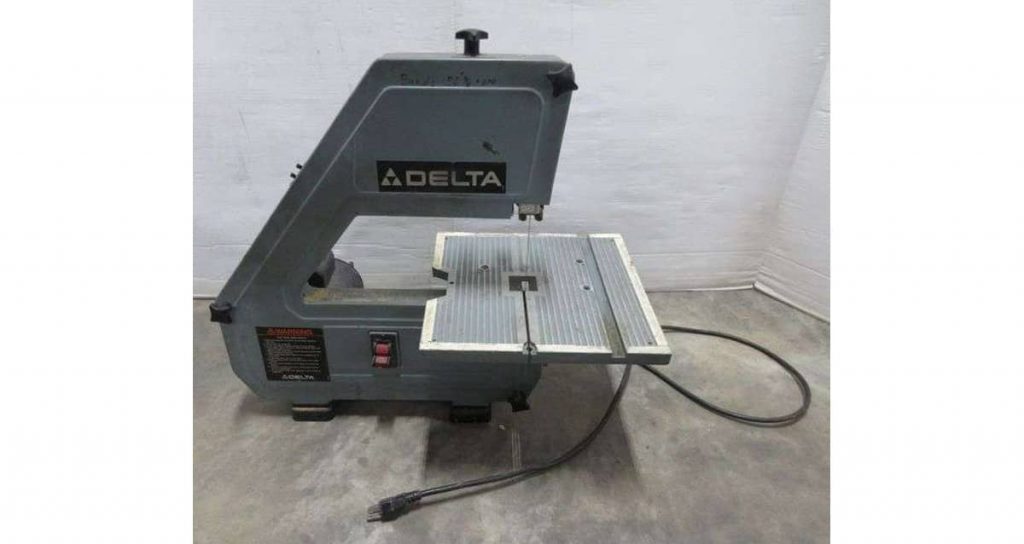

Delta 28-160 Bandsaw

The Delta 28-160 is a reliable and versatile bandsaw that has become a staple in many workshops due to its robust design and consistent performance. Known for its ability to handle a wide range of cutting tasks, this bandsaw is perfect for both hobbyists and professionals who require precision and durability in their tools. With a powerful motor and a sturdy build, the Delta 28-160 is well-equipped to handle various materials, making it an essential piece of equipment for any serious woodworker.

Key Features of the Delta 28-160 Bandsaw

The Delta 28-160 comes packed with features that enhance its functionality and ease of use. Here’s what sets this bandsaw apart:

- Solid Construction: The bandsaw’s cast iron table and frame provide stability and reduce vibrations, ensuring smoother cuts.

- Adjustable Blade Guides: Allows for precise control over the blade, reducing the risk of deflection and improving accuracy.

- Tilt Table: The table tilts up to 45 degrees, offering versatility for different cutting angles.

- Powerful Motor: Equipped with a reliable motor that delivers consistent power for cutting through a variety of materials.

Blade Options for the Delta 28-160

Choosing the right blade for your Delta 28-160 bandsaw is crucial for achieving the best results. This bandsaw is compatible with a wide range of blades, each suited to different cutting tasks. Whether you’re cutting through hardwood, softwood, or metals, there’s a blade designed to meet your needs.

- Standard Blades: Ideal for general-purpose cutting, these blades offer a good balance between speed and accuracy.

- Resawing Blades: Designed for cutting through thicker materials, resawing blades are wider and more robust, providing stability during deep cuts.

- Fine-Tooth Blades: Perfect for cutting thinner materials or making intricate cuts, these blades have a higher tooth count for smoother finishes.

Maintaining Your Delta 28-160 Bandsaw

To keep your Delta 28-160 bandsaw performing at its best, regular maintenance is essential. Proper care will not only extend the lifespan of your bandsaw but also ensure that it continues to deliver precise and accurate cuts.

- Blade Maintenance: Regularly check the condition of the blade and replace it if it becomes dull or damaged. A sharp blade reduces strain on the motor and improves cut quality.

- Lubrication: Ensure that all moving parts are well-lubricated to prevent wear and tear. Pay special attention to the blade guides and bearings.

- Alignment: Periodically check and adjust the alignment of the blade and the table to maintain accurate cutting angles.

- Cleaning: Keep the bandsaw clean by removing dust and debris after each use. This prevents build-up that can interfere with the saw’s performance.

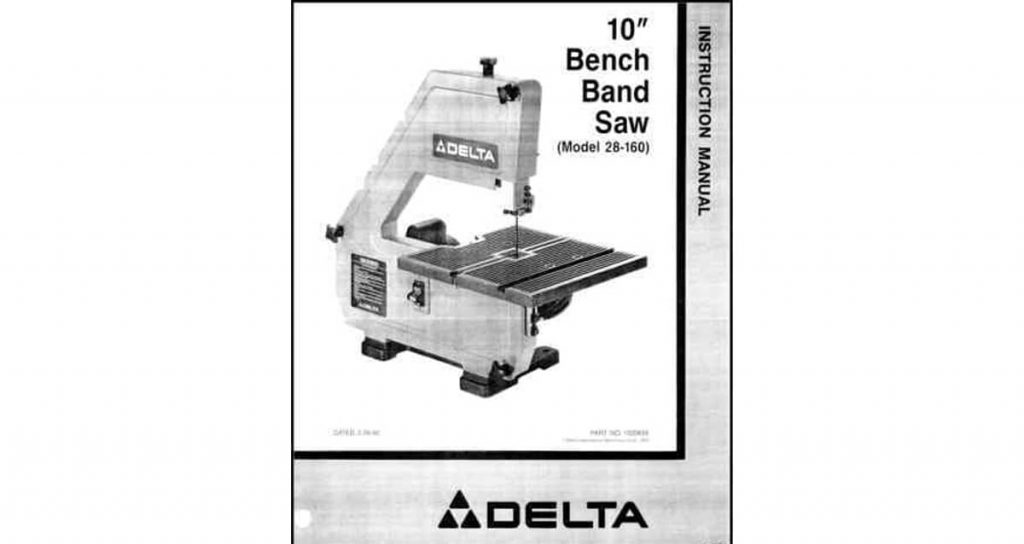

Access Detailed Manuals Online at Bandsawmanuals.com

If you’re looking for comprehensive manuals for your Delta 28-160, visit bandsawmanuals.com to access a wide range of easy-to-download PDF manuals. These manuals are invaluable resources for both beginners and seasoned woodworkers, offering detailed instructions on setup, maintenance, and troubleshooting. Whether you need to understand the finer details of your bandsaw or simply want a quick reference guide, bandsawmanuals.com provides all the information you need to enhance your woodworking experience. Don’t miss out on this essential resource—check out bandsawmanuals.com today!

Ensuring Your Delta 28-160 Bandsaw’s Longevity

To keep your Delta 28-160 bandsaw running smoothly, regular maintenance as detailed in your user manual is essential. This includes:

- Regular Cleaning: Remove debris and remnants from previous cuts to keep the machine clean.

- Lubrication: Apply the recommended lubricants to reduce wear and tear on moving parts.

- Blade Inspection and Replacement: Check for dull or damaged blades that can compromise the quality of your cuts.

- Check for Alignment and Wear: Regularly check and adjust the alignment of your bandsaw’s blade and inspect for any wear on its components.

The Delta 28-160 bandsaw is a powerful and versatile tool that can handle a wide range of cutting tasks. By understanding its features, selecting the right blades, and performing regular maintenance, you can ensure that this bandsaw remains a reliable part of your workshop for years to come. Whether you’re a hobbyist or a professional, the Delta 28-160 is a worthy investment that will help you achieve precision and efficiency in your woodworking projects. For those looking to get the most out of their bandsaw, taking the time to download and consult the manual is a step that can’t be overlooked.